Versatile productions

Finnish state-of-the-art technology

Lanka ja Muovi Oy serves its customers with its highly automated production lines, manufacturing steel wire-, pipe-, sheet metal- and plastic products as well as supplying surface treatments for metal products. A wealth of experience and an extensive customer base have over the years increased our production and customer service to meet the latest requirements in the field. This facilitates flexible and cost-efficient cooperation with our customers.

In R&D cooperation with our customers, we develop products for a myriad of applications. Finding the right solution for the right purpose is important to us. We have been proudly serving our clients since 1955.

Our company also shoulders its responsibility for the environment and quality. We follow an ISO 9001-compliant quality management system and continuously strive to find new solutions with lower environmental impacts.

Our modern production facilities are located in Pori, with a total floor area of some 11,000 square metres.

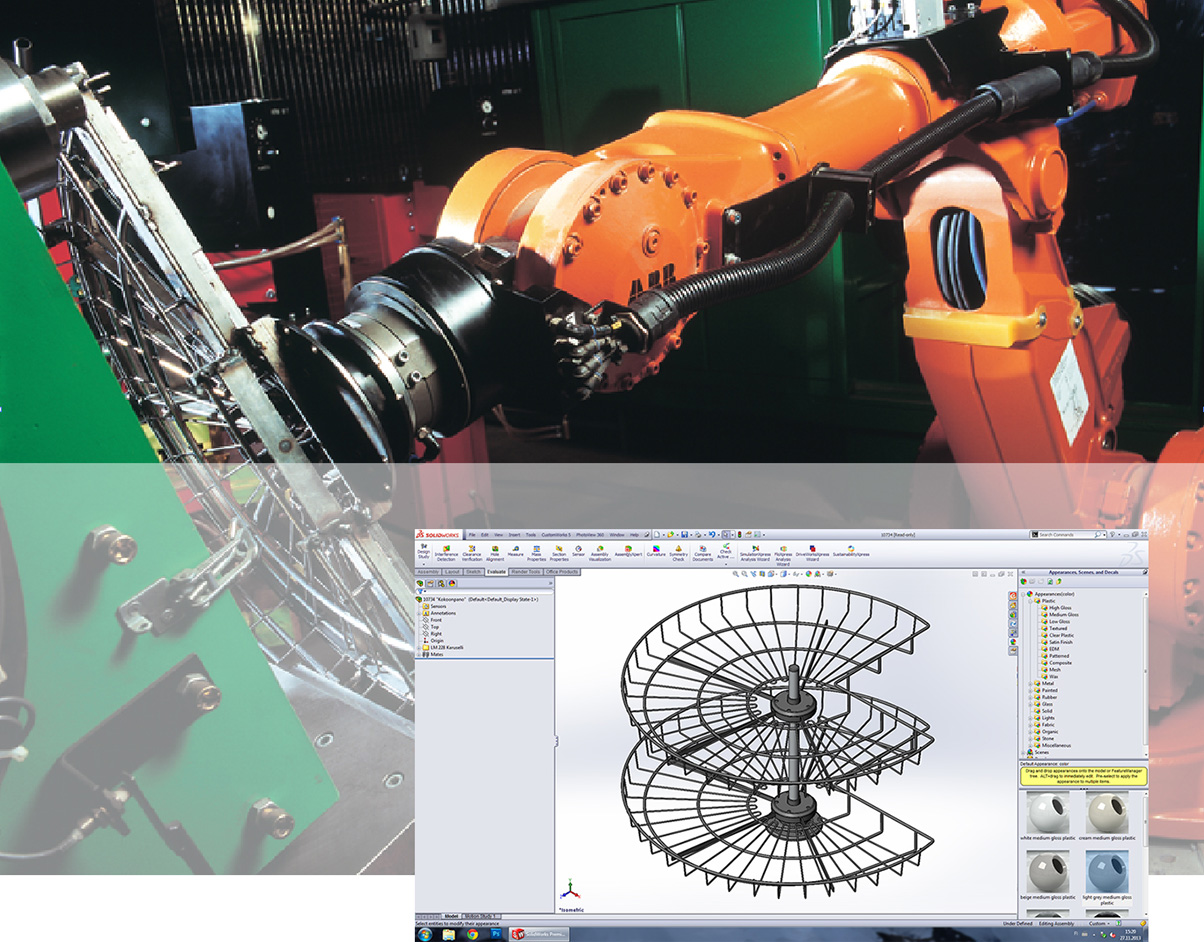

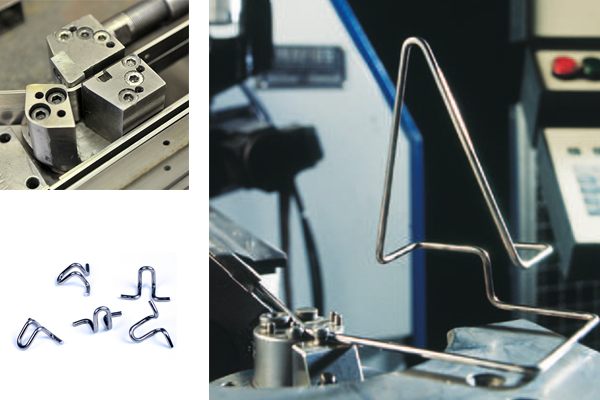

Tailored solutions

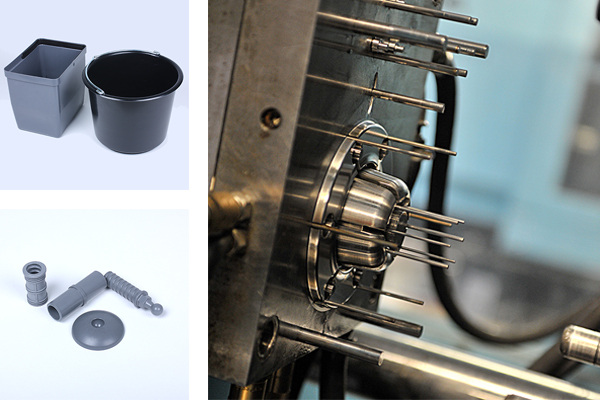

Tailored solutions are our speciality. With our in-house tool manufacturing, we can also make flexible deliveries of prototypes and small production batches possible. In product design, we use the SolidWorks 3D design software, which we can utilise effectively as part of the product design cooperation.

With SolidWorks 3D, we can also create production-level drawings.

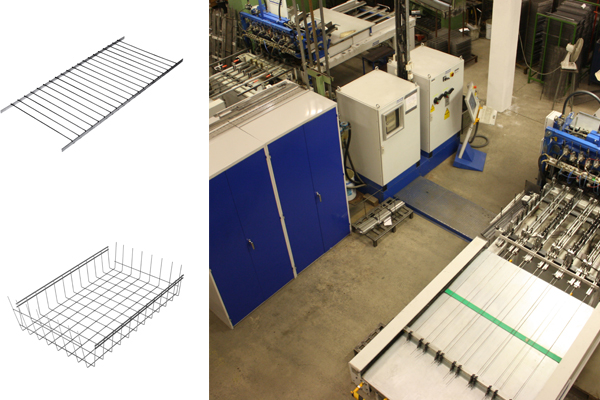

Manufacturing of steel wire products

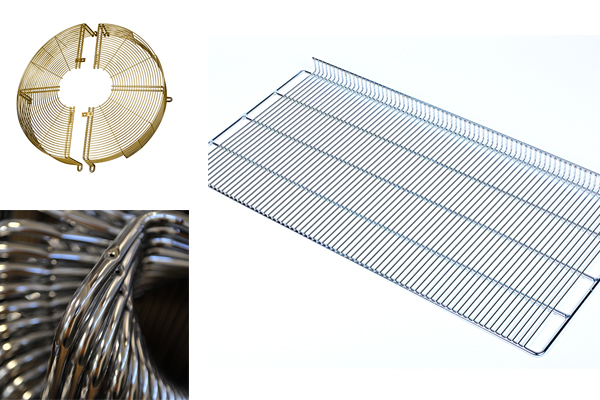

Our modern and varied machinery together with professional skill make the manufacturing of high-quality products possible in both small and large production batches. The products are dimensioned according to the customer’s needs.

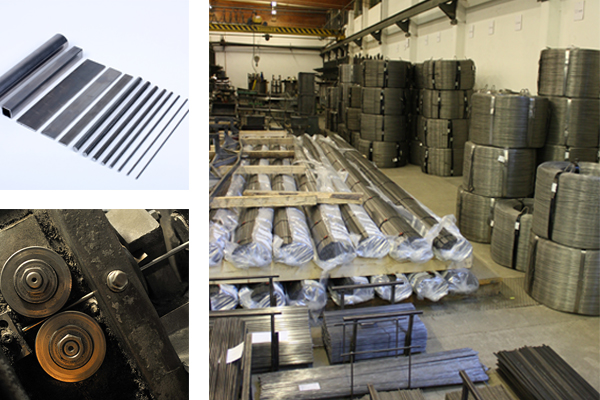

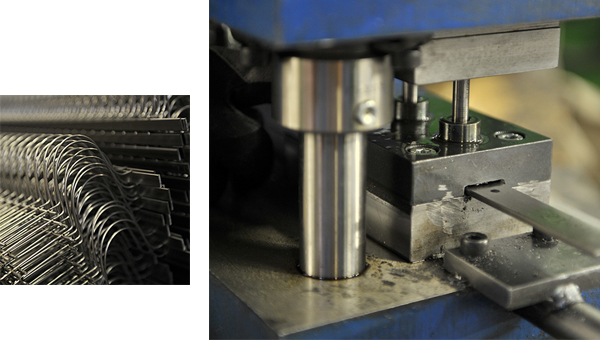

Straightening and cutting

We store steel wire in coils of some 1,000 kg and the wire is straightened and cut to measure from them. The most common wire sizes used by us have a diameter of 1.2–8.0 mm. We also keep several flat bar and pipe sizes in stock. Stainless steel wire is acquired separately according to the customer’s requirements. If necessary, we chamfer the ends of the wires.

Spot welding

We manufacture spot-welded products using automatic spot welding lines, semi-automatically or by hand in the conventional way. Our five automated spot welding lines guarantee the required capacity.

Bending

Wire bending can be done with automatic wire bending machines, which facilitate the cost-efficient manufacture of three-dimensional objects. We also perform bending using the conventional press braking machines.

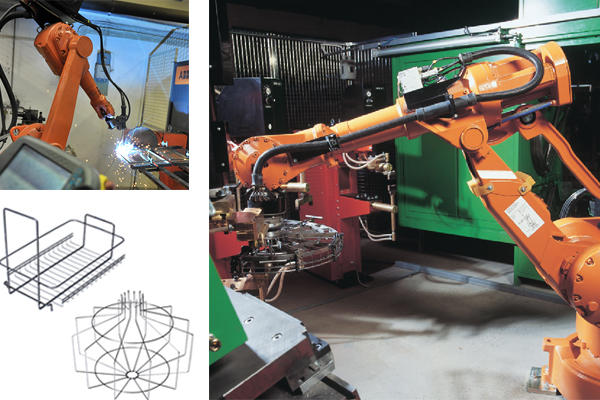

Assembly welding (MIG and spot welding)

The assembly welding of products can be carried out by robotic welding cells as well as by skilled specialists. The size of the production batch, tool weight and product requirements determine the correct manufacturing method. Steel wire, sheet metal, steel pipes and flat bars can be combined in assembly welding.

Other production phases

Our production has several presses: eccentric, hydraulic and automatic pressers.

Sheet metal and pipe work

We manufacture sheet metal and pipe products for various applications. For additional information, please contact our sales department.

SURFACE TREATMENT OF PRODUCTS

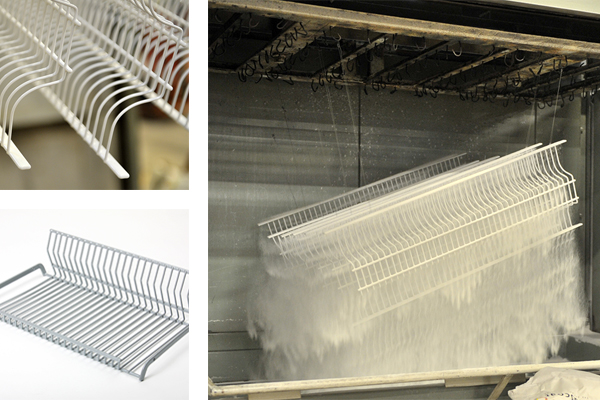

Powder coating

We use the latest powder coating technology. The corrosion resistance of products can be increased with a conversion coating (5-phase washing line), if necessary. Ask for the availability of the product with your own colour number.

LD polyethylene coating

Polyethylene coating is an excellent choice for products that are required to be highly corrosion resistant and have a flexible coating. The most typical applications are dish drying racks and wire racks for coolers. The colour options are white and silver.

Special coatings

The manufactured products are available e.g. galvanised, chrome-plated, nickel-plated, pickled, passivated or with other special coatings. The special coatings are made by our subcontracting partners.

Injection moulding

Injection moulded products can be manufactured from various plastic types. Our smallest machine has a clamping force of 45 tn, the largest 460 tn. The equipment of the injection moulding machines facilitates both competitive small production batches and high-volume production.

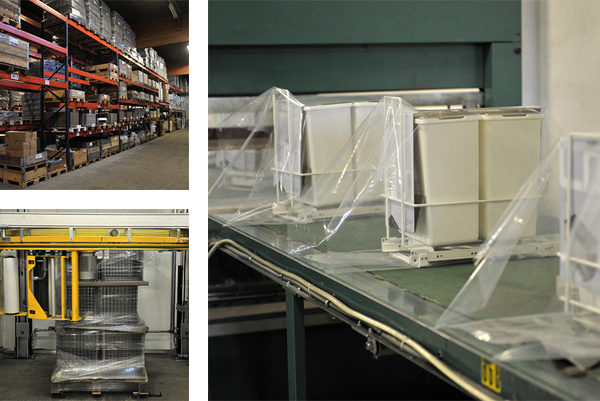

Assembly, packaging and storage

We can also offer assembly services as requested by the customer, such as customer-specific packaging, adding the customer’s components etc. The products can also be shipped in bags, packaged in crates or shrink wrapped. Our large and well-organised storage facilities enable fast deliveries and, by separate agreement, we are also able to store the customer’s production batches.